Ihe onwunwe

| Ahụ | Aluminom (5050 5052 5056 5154) | (AL mg 1%-1.5%, 2%-2.5%,3%-3.5%,5%) | ||

| Mechaa | Achachapụrụ | Agba RAL na-ese | ||

| Mandrel | Aluminom ● | Igwe igwe | Igwe anaghị agba nchara | |

| Mechaa | Achachapụrụ ● | Zinc plated | Achachapụrụ | |

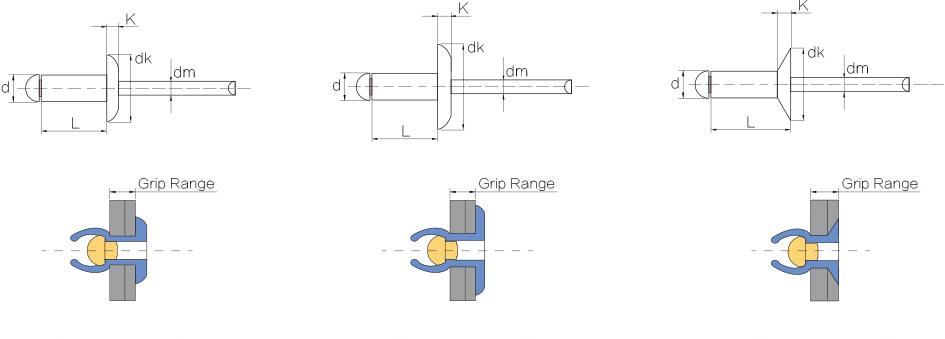

| Ụdị isi | Dome, CSK, nnukwu Flange | |||

Nkọwapụta

| D1 NOM. | KWESỊRỊ NO. & Oghere nha | ART.CODE | OGE JIJI | L(MAX) | D NOM. | K MAX. | P MIN. | SHEAR LBS | TENSILE LBS | ||

| INCH | MM | INCH | MM | ||||||||

| 3/32" 2.4mm | #41 2.5-2.6 | AA32 | 0.020-0.125 | 0.5-3.2 | 0,250 | 6.4 | 0.188" 4.8 | 0.032" 0.81 | 1.00" 25.4 | 70 310N | 80 360 N |

| AA34 | 0.126-0.250 | 3.2-6.4 | 0,375 | 9.5 | |||||||

| AA36 | 0.251-0.375 | 6.4-9.5 | 0,500 | 12.7 | |||||||

| 1/8" 3.2mm | #30 3.3-3.4 | AA41 | 0.020-0.062 | 0.5-1.6 | 0.212 | 5.4 | 0.250" 6.4 | 0.040" 1.02 | 1.06" 27 | 120 530 N | 150 670 N |

| AA42 | 0.063-0.125 | 1.6-3.2 | 0,275 | 7.0 | |||||||

| AA43 | 0.126-0.187 | 3.2-4.8 | 0,337 | 8.6 | |||||||

| AA44 | 0.188-0.250 | 4.8-6.4 | 0,400 | 10.2 | |||||||

| AA45 | 0.251-0.312 | 6.4-7.9 | 0,462 | 11.7 | |||||||

| AA46 | 0.313-0.375 | 7.9-9.5 | 0,525 | 13.3 | |||||||

| AA48 | 0.376-0.500 | 9.5-12.7 | 0,650 | 16.5 | |||||||

| AA410 | 0.501-0.625 | 12.7-15.9 | 0,775 | 19.7 | |||||||

| 5/32" 4.0mm | #20 4.1-4.2 | AA52 | 0.020-0.125 | 0.5-3.2 | 0,300 | 7.6 | 0.312" 7.9 | 0.050" 1.27 | 1.06" 27 | 190 850 N | 230 1020 N |

| AA53 | 0.126-0.187 | 3.2-4.8 | 0,362 | 9.2 | |||||||

| AA54 | 0.188-0.250 | 4.8-6.4 | 0,425 | 10.8 | |||||||

| AA56 | 0.251-0.375 | 6.4-9.5 | 0,550 | 14.0 | |||||||

| AA58 | 0.376-0.500 | 9.5-12.7 | 0,675 | 17.1 | |||||||

| AA510 | 0.501-0.625 | 12.7-15.9 | 0,800 | 20.3 | |||||||

| AA516 | 0.876-1.000 | 22.2-25.4 | 1.175 | 29.8 | |||||||

| 3/16" 4.8mm | #11 4.9-5.0 | AA62 | 0.020-0.125 | 0.5-3.2 | 0,325 | 8.3 | 0.375" 9.5 | 0.060" 1.52 | 1.06" 27 | 260 1160 N | 320 1430 N |

| AA63 | 0.126-0.187 | 3.2-4.8 | 0,387 | 9.8 | |||||||

| AA64 | 0.188-0.250 | 4.8-6.4 | 0,450 | 11.4 | |||||||

| AA66 | 0.251-0.375 | 6.4-9.5 | 0,575 | 14.6 | |||||||

| AA68 | 0.376-0.500 | 9.5-12.7 | 0,700 | 17.8 | |||||||

| AA610 | 0.501-0.625 | 12.7-15.9 | 0,825 | 21.0 | |||||||

| AA612 | 0.626-.0750 | 15.9-19.1 | 0,950 | 24.1 | |||||||

| AA614 | 0.751-0.875 | 19.1-22.2 | 1.075 | 27.3 | |||||||

| AA616 | 0.875-1.000 | 22.2-25.4 | 1.200 | 30.5 | |||||||

| AA618 | 1.001-1.125 | 25.4-28.6 | 1.325 | 33.7 | |||||||

| AA620 | 1.126-1.250 | 28.6-31.8 | 1.450 | 36.8 | |||||||

| 1/4" 6.4mm | F 6.5-6.6 | AA82 | 0.020-0.125 | 0.5-3.2 | 0,375 | 9.5 | 0.500" 12.7 | 0.080" 2.03 | 1.25" 32 | 460 2050 N | 560 2500N |

| AA84 | 0.126-0.250 | 3.2-6.4 | 0,500 | 12.7 | |||||||

| AA86 | 0.251-0.375 | 6.4-9.5 | 0,625 | 15.9 | |||||||

| AA88 | 0.376-0.500 | 9.5-12.7 | 0,750 | 19.1 | |||||||

| AA810 | 0.501-0.625 | 12.7-15.9 | 0,875 | 22.2 | |||||||

| AA812 | 0.626-0.750 | 15.9-19.1 | 1.000 | 25.4 | |||||||

| AA814 | 0.751-0.875 | 19.1-22.2 | 1.125 | 28.6 | |||||||

| AA816 | 0.876-1.000 | 22.2-25.4 | 1.250 | 31.8 | |||||||

| AA818 | 1.001-1.125 | 25.4-28.6 | 1.375 | 34.9 | |||||||

Ngwa

Anyị zuru aluminom oghe njedebe rivet na-eji elu mma aluminum alloy wires.Mgbe riveting, Ọ dịghị mgbe nchara.ma e jiri ya tụnyere ndị nkịtị rivets, na rivet ike dị ala, n'ihi ya, ọ bụ adabara ejikọrọ adụ material.Aluminum pop rivets nwere ike kewaa n'ime a dome isi rivet, countersunk rivets na nnukwu flange isi rivet.And na aluminum alloy ihe nwere multi nhọrọ nke. alu mg 2% 2.5% 3.5% na 5% (5052 5154 5056).

Fixpal oghe ụdị pop rivets nwere uru nke ịrụ ọrụ dị mfe, ọmarịcha mma, ọdịdị mara mma, ihe anụ ahụ dị elu.Nhọrọ zuru oke nke otu akụkụ riveting.Aluminum pop rivets nwere ike iji mee ihe n'ọtụtụ ebe na ụgbọ ala dị iche iche, arịa, nrụpụta ígwè ọrụ, ngwá electronic, ngwá ọrụ, ngwa nri, ngwá ọrụ ahụike, ihe owuwu, ihe ịchọ mma na ebe ndị ọzọ na-agbatị.

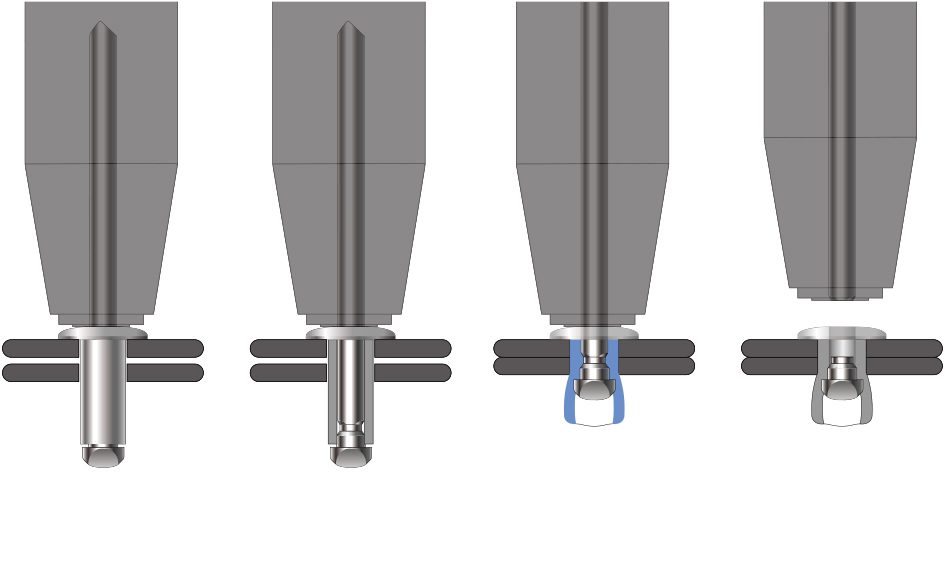

Nsogbu na ihe kpatara ya mgbe ị na-eji rivet kpuru ìsì:

1. Burrs: Mgbe riveting gasịrị, mandrel gbajiri agbaji na burrs na-agafe oghere rivet;ma ọ bụ oghere ndị na-agba agba na-esi n'èzí pụta ka ọ bụrụ spatula burr.

Ihe kpatara burrs: dayameta nke mandrel dị ntakịrị;ihe rivet ahụ dị nro;dayameta nke mkpọpu ala nke workpiece dị oke ibu;nkọwa nke muzzle nke egbe rivet buru oke ibu;

2. Isi ntu na-adapụ: Mgbe a dọkasịrị eriri ahụ, isi rivet enweghị ike ịfụchi wee dapụ na rivet ahụ.

Ihe kpatara ịdaba isi rivet nke isi bụ: dayameta nke mkpuchi ntu buru ibu;rivet ahụ dị mkpụmkpụ, na ọkpụrụkpụ rivet adabaghị.

3. rivet cracking: Mgbe agbajichara, a na-akụri rivet ahụ ma ọ bụ gbajie kpamkpam.

Ihe kpatara mgbawa nke rivet bụ: oke ike siri ike mgbe ọ gbasasịrị annealing ma ọ bụ ọgwụgwọ na-adịghị ọkụ, okpu isi ntu buru ibu.